Professional Foundry Machine Manufacturer

The composition and features of the machine

High-speed and stable running of the main machine--- the running stability and the rotation speed of the tube molds are the key factors affecting the quality of the product. Therefore, the requirement of stability in the running of the main machine is very high. In high-speed operation, the smaller the radial run-out of the tube molds is, the more uniform the wall thickness of cylinder liner will be, and also the more stable the structure performance will be.

The main machine is of cantilever construction with bearing blocks made of cast iron for good shock absorption. The stepless VVVF AC motor and high-performance vector control converter are adopted to drive the spindle rotating via high-performance V-shaped belt, thus to ensure accurate speed regulation of mould. The spindle is also provided with a brake that can ensure rapid stop of mould so as to enhance production efficiency.

Rotary workbench with rapid, smooth and accurate positioning function --- the main multiple machines are arranged on the workbench that can realize multi-position shifting of each machine. The AC servo control is adopted for rapid and smooth rotation, accurate positioning and rotating speed regulation.

Mould inner wall rapid cleaning device --- it is used for rapidly cleaning off residual coatings from the inner wall of tube mould. The spinning brush, which is driven by traversing bogie, moves axially through the mould to clean its inner walls. The brush can be replaced to suit different mould inner radius. The cleaning device contains spraying nozzles and corresponding dust collector.

Excellent spray coating quality--- the inner coating of the tube molds can reduce the impact of metal liquid on the tube molds and reduce the peak temperature of the tube molds, which can effectively prolong the service life of the tube molds, increase the friction force between the tube molds and liquid metal, shorten the time of the pour-in metal liquid to achieve the tube rotation speed, and also facilitate the casting pieces to release from the molds in tube drawing process.

The spray rod movement adopts servo control, which can stabilize the rod moving and make the rod positions adjustable, thus ensuring the uniformity of the coatings. The moving speed of the spraying rod can be divided into three adjustable phases, each of which can be adjusted in moving distance and moving speed to cooperate with the rotation speed of the tube molds and the spraying pressure to meet the requirements of a variety of complex spraying processes.

The real-time monitoring of the temperature of the tube molds and the spray water cooling, the mold temperature has a very big influence on the quality of the cylinder liner, in particular, on the metallographic structure and the hardness of the cylinder liner. If the mold temperature is too high, the wet paint shall inflames, which can cause uneven coatings, and the surface quality of the cylinder liner can’t be guaranteed, and the service life of the molds shall be shortened; If the mold temperature is too low, the pouring paint can't dry out completely, the bubbles are not easy to dissolve out completely before the casting process; when the molten iron of high temperature meets the wet paint, the casting defects such as the white casts and air pores are likely to occur to the cylinder liner.

The cooling nozzles are evenly arranged in the axial direction above the tube molds, which can spray the cooling water to the outer wall of the tube molds as per the parameters of cooling time set-up so that the tube mold temperature can be controlled in the appropriate technology range.

Accurate and reliable tube drawing mechanism-----the mechanism adopts the control method of pneumatic servo system, which can pull out the castings of cylinder liner smoothly from the tube molds. The position and speed of the tube drawing can be set up and adjusted.

Automatic pouring and accurate weighing of molten iron --- automatic pouring device is composed of pouring vehicle, pouring ladle, etc. Pouring vehicle can serve two host machines for pouring on a time division basis. Inclining and pouring speed of the ladle can be adjusted. The automatic weighing device for the molten iron is equipped with the pouring ladle to ensure the consistency of the weight for each batch of cylinders. The weight of the molten iron in the ladle can be displayed on the big screen and the records can be printed.

High efficiency, safe, stable, and flexible automatic control electrical system --- control system use PLC as the control core and use the man-machine interface as the monitoring system to achieve whole process automatic control of centrifugal casting machine and production process monitoring. Control system has the perfect protective measures, such as over-current protection, over-load protection, etc. The process parameters of the host machine and the parameters of the auxiliary machine, such as work positions and velocity, can be adjusted and stored in the man-machine interface, which enables the equipment to have certain flexibility and meet the production process requirement of a variety of cylinder liner castings in a certain range.

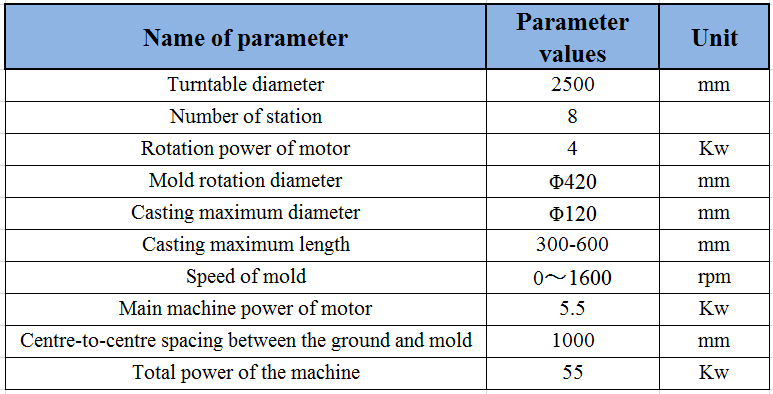

Main technical parameters